Diagnostic and Repair Foundations Course

Learn Appliance Repair

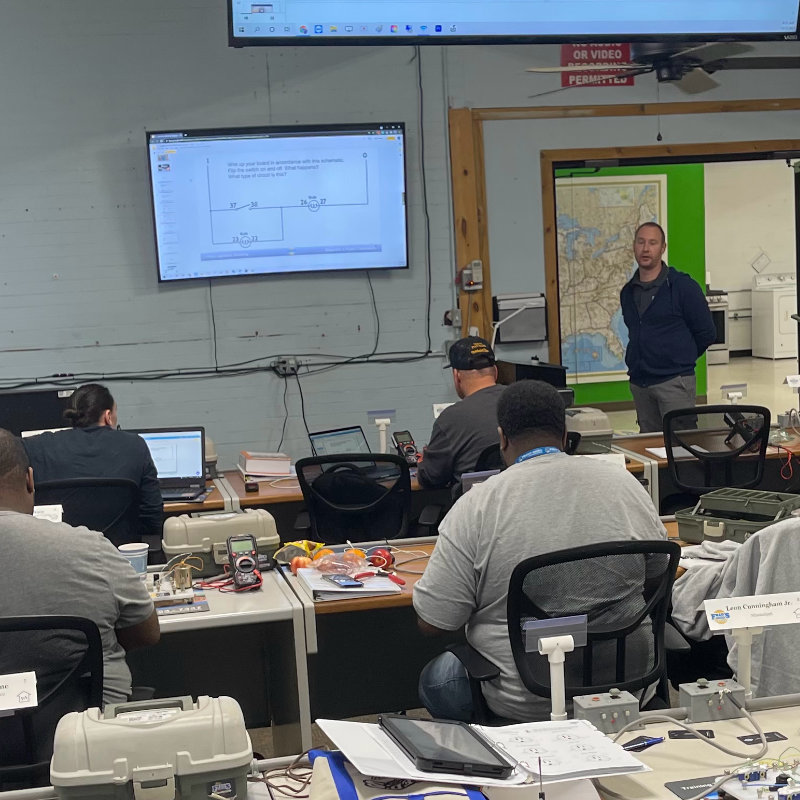

On Campus with industry experts

Our Training

Refrigeration Training

- Diversity in Design: Explore the inner workings of top mount, side by side, and French door refrigerators.

- Defrost Dynamics: Uncover the intricacies of electronic and mechanical defrost systems.

- Technical Foundations: Learn the essential electrical and plumbing requirements for seamless refrigeration.

- Ice & Water Dispensing: Master the mechanisms behind ice makers and water and ice dispensers.

- Temperature Precision: Gain expertise in electronic controls and thermistors for accurate temperature monitoring.

- Brazing, Soldering & Lokring Skills: Develop proficiency with a torch and soldering for durable repairs.

- Sealed System Diagnostics: Enhance your ability to troubleshoot and resolve sealed system issues.

- Sealed System Repairs: Execute precise and proper repairs to maintain optimal refrigeration.

- Efficient Defrost Techniques: Discover the swift, safe methods for defrosting evaporator coils.

- Intensive Focus: Commit an entire week to specialize in refrigeration, elevating your professional aptitude.

Appliance Electrical Theory Training

- Digital Meter Proficiency: Learn the essentials of using a digital meter for appliance repair.

- Circuit Navigation: Understand the journey of electricity through a home and into each appliance.

- Circuit Building: Construct basic circuits with our interactive breadboards to grasp the principles of electricity.

- Switch Savvy: Get to know the various switches you’ll encounter within appliances.

- Diagram Decoding: Become adept at interpreting and reading wiring diagrams.

- Voltage Verification: Learn the techniques to accurately check for power in both 120 and 240 volt appliances using your meter.

Gas and Electric Range Training

- Installation Essentials: Discuss the proper electrical and plumbing requirements for range installation.

- Heating Elements: Examine the function and repair of bake and broil elements.

- Control Mastery: Learn about infinite switches and the nuances of electronic oven and surface unit controls.

- Self-Cleaning Systems: Understand the mechanisms behind self-cleaning systems in modern ranges.

- Temperature Accuracy: Master the methods to properly determine the interior oven temperature.

- Gas to LP Conversion: Explore gas burners and the process of converting from natural gas to liquefied petroleum (LP).

- Ignition Systems Insight: Familiarize yourself with the various types of ignition systems found in gas ranges.

Top Load Washer Training

- Installation Essentials: Understand the installation process along with the necessary electrical and plumbing requirements.

- Stator Washer Skills: Learn to disassemble and reassemble a stator designed washer.

- VMW Washer Workshop: Get hands-on experience disassembling and reassembling a VMW designed washer.

- Diagnostic Proficiency: Master the methods to put each design into diagnostic mode, when applicable.

- Detergent and Additives: Educate on the proper use of detergents and additives for optimal performance.

- Chemical Wear Detection: Identify the signs of chemical damage to clothing.

- Circuit Expertise: Gain insights into the electrical circuitry, including mechanical and electronic controls of top load washers.

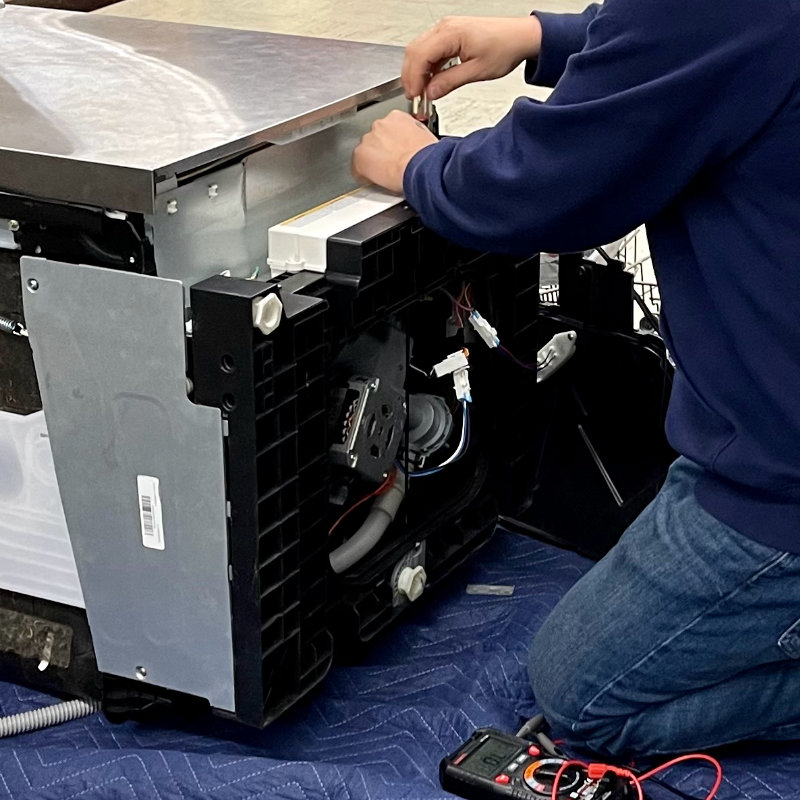

Front Load Washer Training

- Installation Know-How: Grasp the installation process, including the crucial electrical and plumbing requirements.

- Design Distinctions: Understand the key differences between front and top load washer designs.

- Boot/Bellow Mastery: Learn the technique for boot/bellow removal and installation.

- Diagnostic Techniques: Acquire the skill to enter diagnostic mode for each design, as applicable.

- Comprehensive Disassembly: Gain the ability to disassemble and reassemble a complete front load washer.

- Control Systems Insight: Dive deep into the electrical circuitry, mastering both mechanical and electronic controls.

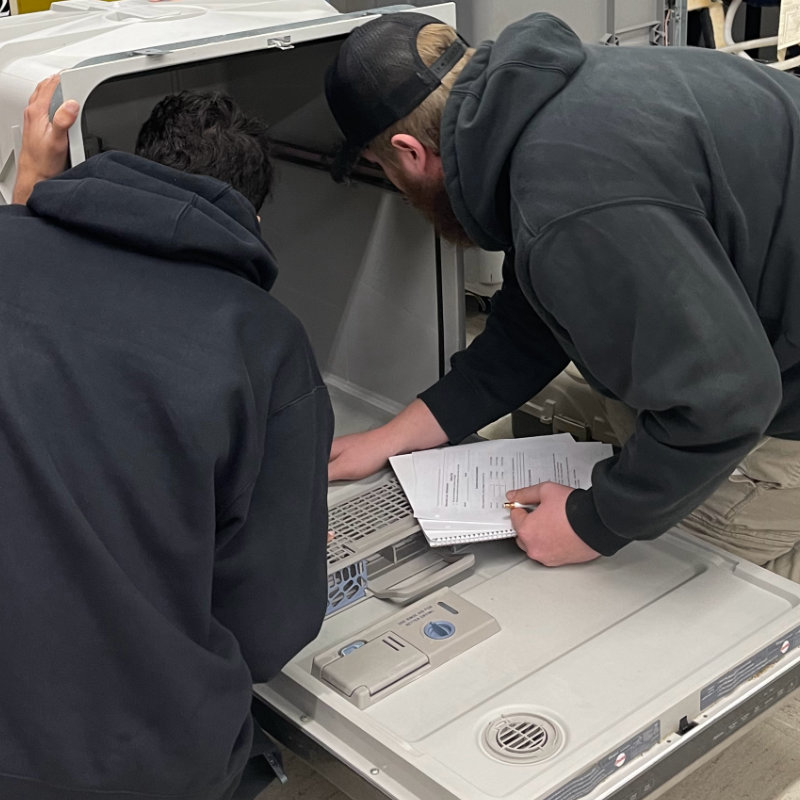

Dishwasher Training

- Installation Standards: Cover the essential electrical and plumbing requirements for dishwasher installation.

- Troubleshooting Installation: Address the common challenges faced during dishwasher installation.

- Detergent Dynamics: Dive into the proper use of detergents and chemicals and their mechanisms.

- Pump and Dispenser Mechanics: Understand the role of pumps and dispensers in water circulation.

- Water Heater Integration: Learn how electric and gas water heaters function in tandem with dishwashers.

- Garbage Disposals and more: Gain knowledge about garbage disposals, instant hot water dispensers, and garbage compactors and their relationship with dishwashers.

Gas & Electric Dryers Training

- Operational Overview: Walk through the workings of electric and gas dryers using wiring diagrams.

- Installation Insight: Learn about the installation process, focusing on venting, electrical, and plumbing requirements.

- Airflow Essentials: Emphasize the importance of proper airflow for efficient dryer operation.

- Vent Alternatives: Explore each alternative to traditional venting systems.

- Steam Dryer Functionality: Understand how steam dryers operate and their unique features.

- Gas Burner and Controls: Dive into the mechanics of gas burners and controls, including troubleshooting techniques.

Microwave Training

- Safe Installation Practices: Review the necessary electrical and venting requirements for proper microwave installation.

- Leakage Prevention: Learn the methods for testing microwave leakage to ensure operational safety.

- Component Fundamentals: Delve into the basic theory and practical testing of microwave components.

- Voltage Troubleshooting: Differentiate between high and low voltage issues and how to address them.

- Non-Heating Diagnostics: Engage in a step-by-step approach to diagnose microwaves that fail to heat.

- Complete Failure Diagnostics: Master a systematic diagnostic process for microwaves that are completely non-functional.

Our Certifications

Build your resume

Course Completion

EPA 608 Type 1 Certified

Appliance Service Fundamentals

EPA 608 Type 1 Certified

EPA regulations (40 CFR Part 82, Subpart F) under Section 608 of the Clean Air Act require that technicians who maintain, service, repair, or dispose of equipment that could release ozone depleting refrigerants into the atmosphere must be certified. Starting on January 1, 2018, this requirement will also apply to appliances containing most substitute refrigerants, including HFCs.

Technicians are required to pass an EPA-approved test to earn Section 608 Technician Certification. The tests are specific to the type of equipment the technician seeks to work on. The 608 Type 1 test we register you for is an online, open-book test. Section 608 Technician Certification credentials do not expire.

Institute of Appliance Service Technicians

The Institute of Appliance Service Technicians was created to help the appliance repair industry set a standard for appliance certification. Our goal is to ensure that every appliance repair technician is trained properly in the latest diagnosing techniques. We want a safe work environment and with appliance repair, the work environment is almost always the customer's home. The stakes couldn't be higher when it comes to knowing the proper techniques when repairing appliances.

Formed in 2015, the focus has been on knowing the basic fundamentals of appliance repair. The constant demand for appliance repair technicians require companies to high and train their technicians from the ground up. The ASF Certification was assembled to test the user on the basic fundamentals of repairing appliances today.

Appliance Service Fundamentals

The Appliance Service Fundamentals Certification(ASF) is a multiple choice, 140 question test that covers appliance electrical theory, cooking electric, cooking gas, customer service, dishwashers, laundry, microwaves, part identification, and refrigeration.

The test is a challenge for someone brand new to the industry and we recommend getting at least 6 months to a year of appliance repair experience before attempting this test. This test is available online using Proctor U.

Course Pricing

Are you ready to join the industry's best trainers?

We're waiting for you.

Diagnostic & Repair Foundations

3 week hands-on training$4,200

3 week hands-on course including refrigeration

- Diagnostic & repair training on all major appliance types

- Continental breakfast & delicious lunch prepared M-F

- ASF & EPA Type 1 certification

- Cancel or change your reservation anytime before class without fees

Student Housing

3 week stay$60 / Night

- 20 night stay in a 2 bedroom flat with a private bedroom

- All amenities including laundry, kitchen, & internet

- Campus experience allows for collaboration with fellow students

- Only a 3 minute walk from our Academy classroom & lab

- Living room space with TV

Our Alumni

Congrats to our graduating March 2024 class

Congrats to our graduating February 2024 class

Congrats to our graduating January 2024 class

Congrats to our graduating December 2023 class

Congrats to our graduating October 2023 class

Congrats to our graduating September 2023 class

Congrats to our graduating August 2023 class

Congrats to our graduating July 2023 class

Congrats to our graduating June 2023 class

Congrats to our graduating May 2023 class