There is nothing more frustrating than reaching for the exact tool you need, only to find it missing. Whether you have an organized toolbox or a rattling hardware bag, there always seems to be at least one missing piece – if not more – at any given time. This is a struggle of repair technicians and handy family members since time immemorial. Someone (likely your own self) has always made off with your best hammer or left the wide screwdriver where they last used it.

If you’re regularly performing repairs and tired of hunting for the right tools, this guide is for you. As experienced technicians, we’ve been where you are and have learned a few tricks along the way.

1) Wrap Tape Around Handles to Mark Tool Sets

Grab some colored electrical tape or, better, a stretchy fabric tape that sticks and provides some traction. Now wrap one colored line of tape around the handle end of every screwdriver in your complete set. Pick a different color and wrap the handle ends of your combination wrenches. Use thinner rings of tape in a third color to mark every socket in your socket wrench set, and another for your socket driver tips.

This color-coding makes it quick and easy to identify tools by the set they belong to, then return them to the set. If you want to get clever, use a tape-code to indicate the order or numerical value of each set item. now it’s even easier to put them away in-order or grab the right one from the tools at-hand during a repair.

2) Use Portable Kit with Locking Slots

Tool boxes and bags only get cluttered when tools are allowed to rattle around in the bottom. If you only had a hammer and a few standard-sized screwdrivers, that would be one thing. But in appliance repair, there are a few more tools than that to contend with. Whole sets of drivers or wrenches are sometimes necessary to address every fastener (or unexpected fastener sizes) in a repair.

The solution is kits and racks with locking slots. Keep your combination wrenches aligned in a slotted flat, and your screwdrivers organized by size and head type. Your sockets should be locked into rows or tucked into the wrench case. All of your organized tool kits can then be packed into a single tidy bag or toolbox.

3) Try to Put Tools Down Into Their Kit-Slot

When you pick up a tool for the first time in a project, you take it out of the stored slot. Identifying the right one is easier when everything is already in order. So when you put down the tool, you have two options. You can set it by your knee or on a near surface for a quick grab.

Or you can set the tool back into it’s assigned place in the holder.

For active repairs where you are constantly grabbing and re-using a tool throughout the process, keeping your tool to the side can be handy. However, if there are multiple phases and you’ll be coming back to a tool later, put it down into the case. This way, there’s no risk of the tool being out of place when you need it next – and you can double-check that you’ve got the right size before continuing.

4) Clean Your Workspace Before & After Every Project

Every technician has misplaced a tool in the middle of a project. It’s often under your knee or rolled just below the lip of the appliance currently being deconstructed. This is perfectly normal and the tool always turns back up when you need it. But what about the misplaced tool that can’t be found, or worse, whose absence isn’t noticed when it’s time to go?

The answer is a habit of clean workspaces. Start by clearing the space you’re going to work in before starting a repair. It helps to put down a drop-cloth and these days, it’s considered courteous and necessary. Work entirely within your cleaned space and make sure to place your tools somewhere easily seen within that space. Not only will you lose fewer below the knee, you’ll find them more easily at the end of the repair.

When the project is done, clean the space again. Gather and set your tools into their proper slots and take inventory. If anything is missing, carefully work your way out from the clean area. Chances are that any missing tools have not rolled far.

5) Sturdy Pockets & Timely Pocket Emptying

Having a handy set of pockets can also be extremely useful when it comes to not losing your tools. Prioritize pants styles that have deep, sturdy pockets, loops, and side-pockets for docking your at-hand tools. Pockets are also a great place to put tiny screws and bolts that should not be lost.

Get in the habit of using your pockets instead of nearby surfaces and the rewards will reap themselves over time. The pocket method prevents screws and drivers from falling behind, between, or inside the appliances you are working on.

Along with this method, be sure to empty your pockets in a predictable routine. Check your pockets when packing up from a repair, again at HQ before heading home, and one more time for good measure before those pants go into the washer.

6) Have a Cup for Screws and Bolts

Speaking of keeping track of smaller hardware during a repair, it helps to have more than one solution for holding onto screws. Some technicians use a large magnet. Some carry an extra cup or bowl (perhaps with a lid) to hold the mounting screws that must be removed to investigate or repair the insides of an appliance. Any solution that prevents you from losing screws is better than setting them in a tiny rolling pile on any nearby surface.

7) Inventory and Sort Tools as Needed

lastly, remember to inventory your tools. With the tape markings and organized holders, it should be easy to identify if all your tools are present at a glance. But even if you are carrying a tool bag rattling with loose implements -remember to do your inventory. Inventory before you head out for the day as you unpack at the repair, before you leave each site, and when you get back to HQ each day. Just a quick eyeball count of your tools by type can help prevent the occasional frustrating oversight of losing one tool in your complete set.

—Are you making plans to earn or renew your appliance repair certification? Fred’s Appliance Academy is now online and ready to help. Contact us today for more appliance repair insights from the pros or to talk about certification course enrollment.

How to test a gas range ignitor

Congrats to our graduating March 2024 class

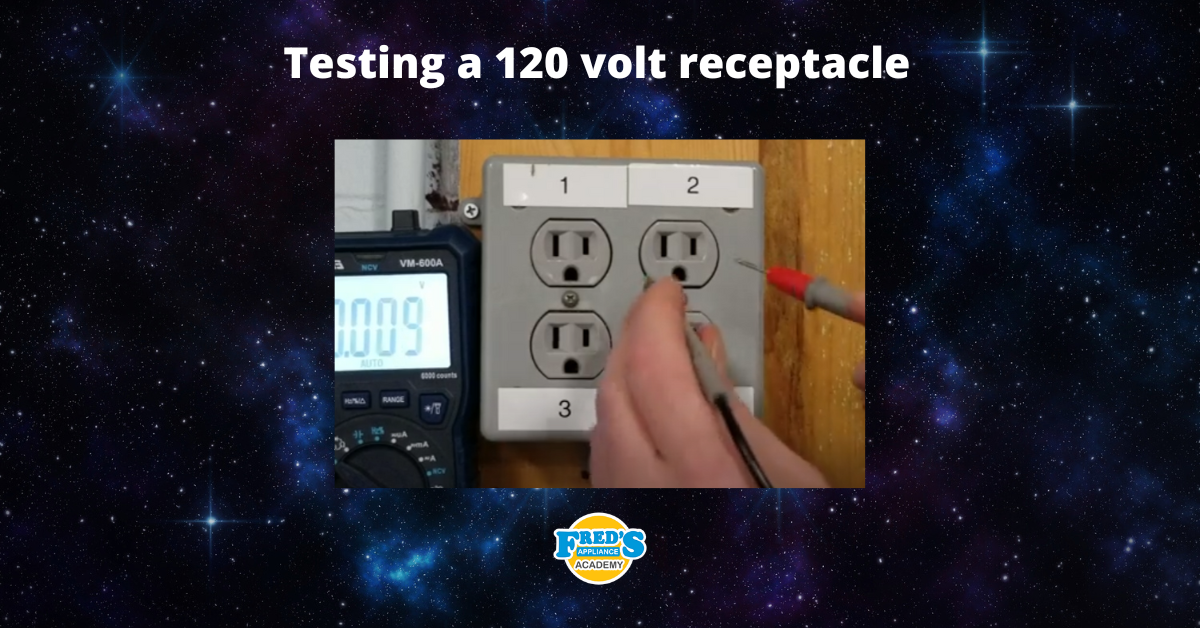

How to test a 120 volt receptacle

Congrats to our graduating February 2024 class

Why Is Your Dishwasher Soap Not Dissolving? (5 Easy Fixes)

Refrigerator Dripping Water Inside? 5 Quick Fixes

Appliance Industry 2023 Q4 Results

Congrats to our graduating January 2024 class

Clever ways to use airbags to level your appliances