Building a good toolbox is about more than just a checklist of screwdriver types and wrench sizes. A good set of tools, especially for a repair technician, is all about practical usage. Some tools are just plain easier to use than others. Some are more efficient, providing multiple functions in one handle or kit. Some are easier to hold onto, some are easier to fit into tight appliance-cabinet spaces. The right tools for a technician’s tools should be chosen with care. Over years of experience, you’ll learn which tools are better than others. But why go through trial-and-error with a beginner’s collection when you can learn the tricks early. What do some appliance technicians look for when building a toolbox or replacing old favorite tools?

1. Rubberized Handles

The best tool handles are easy to grip, but don’t get sticky over time. Look for handles with rubberized grips, but not handles that are entirely a soft-grippy material. Look for handles that are a mix of hard plastic and embedded gripping pads. Sturdy, textured plastic is a good fallback and sometomes the better choice in tool overall.

These tools are easier to hold, with and without gloves, and are less likely to fumble when you’re elbow-deep in an appliance.

2. Magnet-Tipped

There is nothing more frustrating than dropping a screw into appliance housing. Some repair-jobs require you to insert and secure a screw so deep in a pit that is too small for manual alignment. There are a few solutions to this dilemma, and the absolute best from experience is a simple magnet-tipped screwdriver. look for magnet-tip with all or most of your screwdrivers, including socket-screwdriver sets. Magnets are great in many ways for holding or retrieving small components. We’ve spoken several times on the value of magnets in various capacities. You can also use magnets as a cup for screws and brackets, and as a way to fish lost screws out from behind or between non-ferrous furniture. But all appliance technicians eventually discover that magnet-tipped screwdrivers are practically mandatory.

3. Easy Spin Back-End

Securing some screws and bolts takes longer than others. Spinning tools work much more quickly when there is a spinning piece on the back of the handle. By bracing your palm-heel on the spinner, you can press a screw firmly into place while driving it home by spinning with your fingers. This way, you never have to let-up on a screw before it has secured the intended prices, and you don’t have to adjust your grip.

This is particularly helpful when securing brackets that are held together with some tension by a short screw. Letting up to twist the screwdriver can lose your alignment and invalidate your next twist, while the spinning end allows constant pressure and greater wrist comfort.

4. Modular Kit

Few things are more useful than a tool with a complete set of interchangeable heads. A modular kit is just as useful for screwdrivers as it is for socket wrenches. Having an array of heads in various sizes, along with other helpful components that often come with kits like extenders, can ensure you are always prepared for a repair, no matter what size or shape it’s fastening bolts might be.

As an appliance repair technician, you’ll want a set of screwdrivers, socket wrenches, plumbing wrenches, and nut-drivers. Your multimeter should also come with a set of interchangeable probes. Many of these can be bought in modular kits, and the rest can be bought in elegant size-ranged solid kits. In fact, anything you need that comes in a modular, self-contained kit is often the better choice.

5. Easily Replaceable Pieces

Another essential feature of good tools is being replaceable. Tools get damaged, lost, left behind, and permanently lent. Even more commonly, pieces from your kits will go missing. We generally lose the occasional screwdriver bit, socket, or allen wrench along the way. It’s important to be able to quickly replace each piece or a section of each set.

The best tactic is to choose common brands, and universal connector-types and sizes. Know your stats and before you choose a toolset, make sure you can buy replacements for its parts. Individual tools can also be chosen by how easily you can get replacements that perfectly match your workflow.

6. Stubby, Long, and Flexible

Appliances come in all shapes and cabinet designs. Often, you’ll need to manage a screw or nut in tight quarters and strange conditions. This means you sometimes need things like both stubby and long tools to fit in incredibly tight spaces or long, narrow reaches. Flexible tools, which can twist around a corner, are also sometimes very useful. Look for these variations and include them in your toolkit.

Modular kits often include straight and flexible extensions. A small collection of basic stubby tools can fill your need where kits do not.

7. Visually Distinct

It also helps if your tools are easy to identify at a glance. Brightly colored handles and distinct designs can help you quickly pick the right tool without looking closely. If all your tools look approximately the same, as often happens when your tools come from the same brand, you can customize. As a technician or as a team, there are many ways to make your tools visually distinct.

The quick DIY version is colored tape. The long-term professional coloring option is powder coating.

Building Your Technician Toolbox

Becoming a capable appliance repair technician takes a few months of intense training and a year of practice. Becoming a pro technician, however, is done with years of experience and life-lessons you can only learn on the job. But you can definitely accelerate your achievements by learning the tricks of the old-hands. From troubleshooting methods to building the perfect toolbox, we’ve been collecting these pro-technician tricks for decades, learned by hundreds of technicians along the way. To learn more about professional appliance repair, take hands-on lessons with the pros, contact us today! And if you’re just looking for more handy tips to become a better technician, our blog has many experience-based guides to explore. We look forward to hearing from you!

How to test a gas range ignitor

Congrats to our graduating March 2024 class

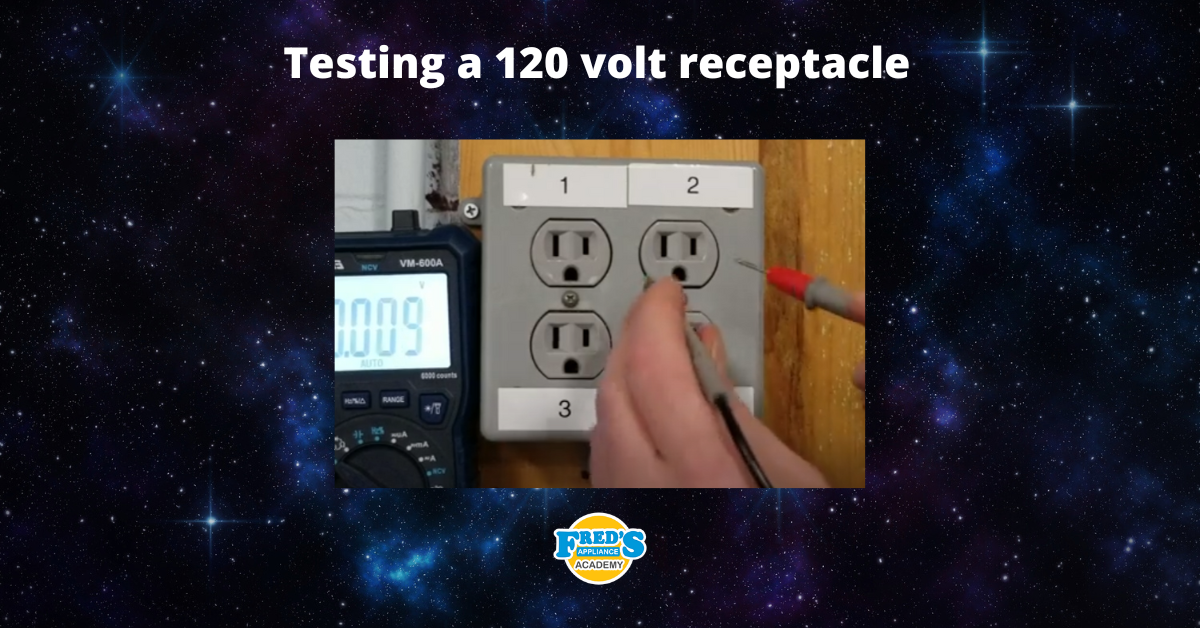

How to test a 120 volt receptacle

Congrats to our graduating February 2024 class

Why Is Your Dishwasher Soap Not Dissolving? (5 Easy Fixes)

Refrigerator Dripping Water Inside? 5 Quick Fixes

Appliance Industry 2023 Q4 Results

Congrats to our graduating January 2024 class

Clever ways to use airbags to level your appliances