Appliance repair is not always as graceful as we might prefer. Sometimes, you need to get head-down, or shoulder-deep in an appliance to fix it. In that moment, you don’t have time to reach into your toolbox for the right item. You also probably don’t have a spare hand to hold your next-needed tool at the ready. In these moments, it’s pretty darn handy to have a way to dock and tether your tools where you need them.

Imagine, for a moment, being able to stick a screwdriver to the appliance cabinet or your chest for just a moment while you work. Take it from the pros; you have options. In fact, any technician can choose two or three ways to dock tools and keep them handy when you need them. Let’s take a deep dive into your options when shoulder-deep in a home appliance.

Tool Belts and Holsters

The most traditional option for docking your tools is, of course, the tool held. A tool belt can definitely keep your best tools within reach, but not always at the right angle when you’re working on appliances. A toolbelt helps you prepare a set of tools for a job and, as long as you’re not halfway into an appliance or squeezed between a cabinet and wall, you can reach what you need.

Tool belts can be improved with the addition of holsters and harnesses, often up around the shoulders where we do the tightest work. With the right tool-harness combination, you can keep most of your best or current tools right where you need them when you need them. Of course, with the wrong combination, you’ll drop tools all over the place.

Gripped in Your Teeth

The solution we all naturally turn to is, of course, gripping a needed tool in your teeth. We’ve all been there. In the moment when you’re holding a screw in place and just barely have enough light to get the angle, you will absolutely grip a screwdriver in your mouth and retrieve it to get the job done. First, let us remind everyone that, yes, this is unhygienic and particularly inadvisable in the age of corona. All the more reason to find a better alternative that works effectively. All technicians have resorted to gripping a tool between the teeth in the thick of a repair. Young and old, beginners and pros. Often, this is the moment when we begin to realize that velcro and magnets might be more appealing options if done correctly.

Ideally a last resort for any situation.

Velcro

The workman’s solution to on-demand docking is velcro. Stick-on or sew-on, velcro strips can turn just about any tool into something that you can easily park for a moment and retrieve a moment later. Put the receiving velcro strip onto a harness, vest, jacket, or belt. Just as long as it’s something you’re always wearing when you’re on the job. You can also choose to adorn all of your work shirts with velcro strips in strategic (even stylish) places to make your workflow easier on the job.

The downside to velcro is that it usually alters the grip of your handles. Stick a strip of velcro on your screwdriver and, naturally, the screwdriver handle will now have a velcro bump. If you don’t care, that’s great and you can take full advantage of the velcro trick. If you do care, then velcro may only be an ideal solution for some of your tools with better mounting points or less balanced grip.

Tether Lines

Your next option is one that is ingenious sometimes and frustrating at others. Tether lines can be exactly what you need when you need them. A tether line essentially keeps a needed tool from falling. You can tether a tool to your wrist or to a hole or bolt inside the appliance. You can tether a tool to the wall next to you or to your toolbelt so it doesn’t fall.

The most useful thing about a tether line is that your tools can’t fall out of reach while tethered. They will not fall into the appliance cabinet or clatter to the floor when your hands are full. Tethers can be firm or stretchy, long or short. Tethers can also be used to fish fallen tools back by pulling on the lines.

That said, we strongly advise using tether lines selectively. They are deadly useful in the right circumstances but too many can easily become a tangled mess. Keep your tethers short and, if possible, secured to a cabinet or wall nearby instead of to your moving body.

Magnets

Last but certainly not least is your option to use magnets. Magnets are a fantastic appliance repair trick in a number of ways. For example, a large magnet stuck to the side or top of an appliance can be used to hold screws and to dock ferrous tools. A magnet at the tip of your screwdriver can hold screws in place instead of dropping them when grip is lost. You can also use magnets to dock ferrous screws, nuts, bolts, and tools just about anywhere.

Magnets can be washed, it’s important to note. This means you can sew magnets into your harnesses or clothes and then use, say, your shoulders as a docking point for ferrous tools. You can attach a magnet to your toolbelt, harness, or vest and they will be just fine after going through the wash. Magnets are a great way to keep your tools nearby. You can even make a magnet cuff for smaller ferrous objects you want to keep close-at-hand.

—Tethering your tools is an important part of acing your appliance repair technique. Why reach and fish for the tools you need when you can keep them docked to the nearby appliance cabinet or on your person. Here at Fred’s Appliance Academy, we are proud to provide deeper understanding and industry insights to appliance technicians everywhere. Contact us today to learn more about learning appliance repair. We are always happy to greet someone new or meet an old friend.

How to test a gas range ignitor

Congrats to our graduating March 2024 class

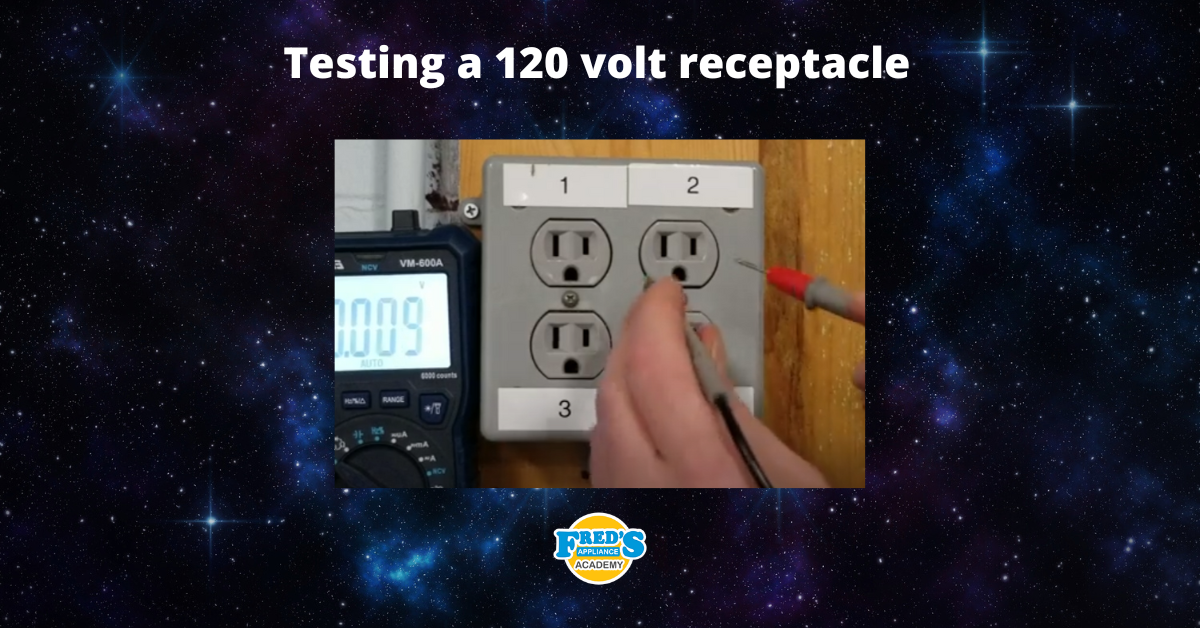

How to test a 120 volt receptacle

Congrats to our graduating February 2024 class

Why Is Your Dishwasher Soap Not Dissolving? (5 Easy Fixes)

Refrigerator Dripping Water Inside? 5 Quick Fixes

Appliance Industry 2023 Q4 Results

Congrats to our graduating January 2024 class

Clever ways to use airbags to level your appliances