Fred's Appliance Academy

August 27, 2018

Tools

The difference between DIY appliance repairs and professional work is the experience. Once you’ve repaired a few different models of the different major appliances, their systems make sense. Basic problems become almost intuitive to troubleshoot. You gain familiarity with the quirks and individual specs in how different companies diagram their appliances’ wiring. Each time you take a machine apart and put it back together, you learn something new.

But knowledge and experience are not the only things that separate professionals and people who can take a shot at fixing their own appliances. Many times, it just comes down to the tools you have available. Though almost every repair needs a flathead screwdriver, sometimes you need a hygrometer. You often need a socket wrench, but sometimes you can’t move forward until you have a bit of alumilastic.

Specialty tools are non-negotiable, and that’s even more true if you want to offer repair services for gas-powered appliances. Natural gas is dangerous when you don’t know what to look for or you don’t have the tools to get the job done correctly. Here are seven must-have tools that you need to keep in your truck and that you need to be familiar using.

Do you have the right tools for detecting natural gas leaks?

When gas-powered appliances break down, it’s not always because of a problem with the natural gas. In fact, gas appliances are just as liable to have clogged filters, water leaks, and malfunctioning control pads as anything else. But whenever you’re troubleshooting, repairing, or replacing appliances that use natural gas, you need to keep an eye and nose out for leaks.

These tools keep the area even safer:

1. Make sure the area is clear with a gas detecting pen.

Your first priority is to keep an area safe. Using detection devices that can alert you when the chemicals in the air change is essential. A directional pen also helps you detect the sources of leaks and different gaseous contaminants. Look for handheld models that detect every type of gas, from methane to butane, and carbon monoxide. This one tool can help you find invisible cracks or decide when an appliance is no longer safe. Directional fog emitters, rather than smoke matches, can also help you detect patchy airflow.

2. Leave behind carbon monoxide detectors.

Sometimes you’re going to have customers that don’t have carbon monoxide detectors. Always have a few extras in your truck so you can install one in the utility closet or near the gas-powered appliance if you don’t see one nearby. Your job is only to fix the malfunctioning appliances, but this extra service makes your company memorable and keeps your customers safer.

3. Have some gas leak detector fluid for reinstalled connections.

When you’re down making whatever repairs you need to perform on a gas-powered appliance, it’s time to reconnect it to the gas line. Make sure you have gas leak detector available to wrap around the connection points. It will bubble at the source of a leak or loose connection so you can make adjustments before powering on the device. Soapy water will work in a pinch, but the leak detector is more professional.

4. Make the natural gas connection leak-proof with yellow Teflon tape or pipe thread compound.

Always carry both of these options in your truck. Depending on the model of the appliance you’re dealing with, one compound is better for sealing the supply line adapters than the other. These materials make sure there isn’t any extra space for natural gas to get into the house. But always doublecheck which parts should have added compound and which should be left alone.

Having the right tools on hand always make an appliance repair job go smoother. Go to Fred’s Appliance Academy for more ways to prepare for complicated jobs and to expand your business.

(800) 781-1814Text or ring! ring!

Live ChatClick to say hi

Apr. 05, 2024

How to test a gas range ignitor

Mar. 29, 2024

Congrats to our graduating March 2024 class

Mar. 22, 2024

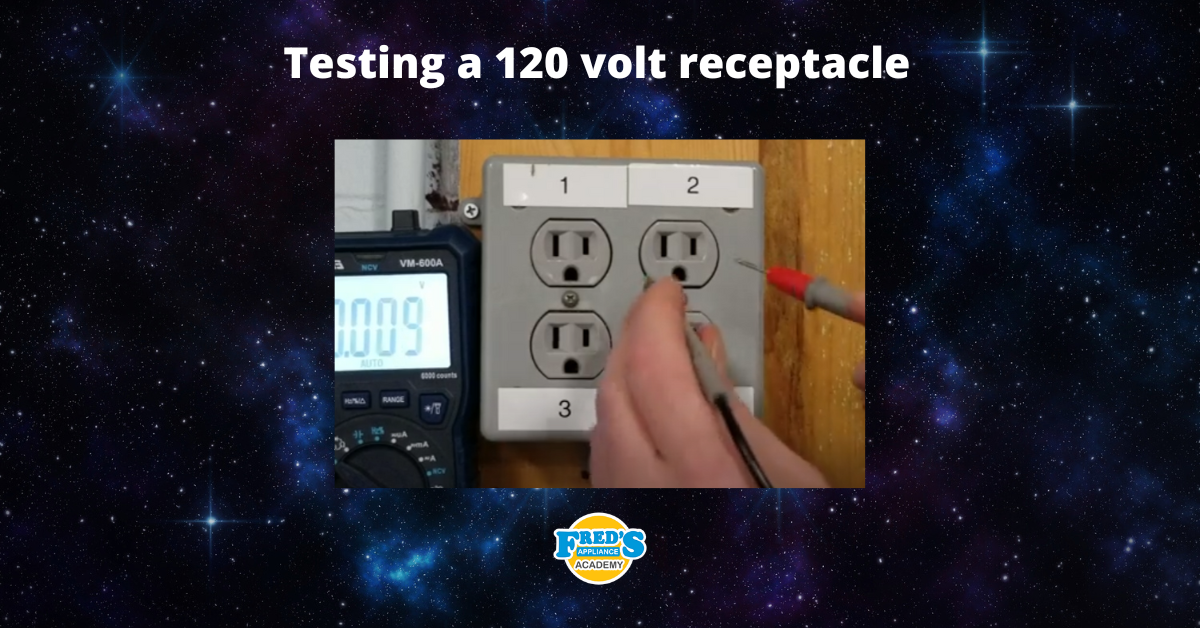

How to test a 120 volt receptacle

Mar. 01, 2024

Congrats to our graduating February 2024 class

Feb. 05, 2024

Why Is Your Dishwasher Soap Not Dissolving? (5 Easy Fixes)

Feb. 05, 2024

Refrigerator Dripping Water Inside? 5 Quick Fixes

Feb. 02, 2024

Appliance Industry 2023 Q4 Results

Feb. 02, 2024

Congrats to our graduating January 2024 class

Jan. 26, 2024

Clever ways to use airbags to level your appliances

Jan. 12, 2024