No one starts out as an appliance repair expert. Even if you have a natural talent for appliances and plumbing, everyone makes beginner mistakes. Before you’re trained or have repaired a few dozen appliances, most home handy family members have duct-taped and questionably plumbed a few things along the way. It takes hours of manual reading and months of hands-on training before you’re ready to go solo repairing appliances for paying customers. While classroom learning is essential to get started, there are also some things you only learn when looking at real in-home appliances that have been used (and repaired) by possibly hundreds of different people over the years. The grime, the DIY hacks, the things that work, and the things that don’t will blow your mind. Not to mention all the little tricks you learn to get the job done in these crazy situations.

In honor of all the old pros and the incredible lessons you can only learn from worst-case scenarios, we’re sharing our favorite appliance repair lessons from years in the field.

1) There are appliances older than you that are still running.

No matter how old you are, there is a water heater out there older than you are. Some brands and models were inexplicably made like tanks. Some climates are also perfect for appliance preservation. Dry air, moderate temperatures, and clean homes can sometimes keep an appliance alive for decades after it should have rattled to a slow death.

If the appliance really is in good repair (check for rust on the inside and back-sides) you can contribute to its legacy by becoming the next in a long lineage of repair technicians. In most cases, however, you’ll find yourself helping the family retire that artifact and install something new that suits the house. No manual will prepare you for how old some appliances will live. Give a salute, it’s served well.

2) Watch the old pros. Their toolbox tricks will save years of your life.

Whether your services sends teams or solo technicians, pay attention to the old pros when you work side-by-side. Over the years, repair technicians learn, invent, or inherit a whole toolbox of useful tricks. The things you can do with a magnet, chain, and screwdriver extender look easy when you see it done, but you’ll appreciate every one when they help you fish a dropped screw out of the washer housing or reach an impossible angle.

This, by the way, is true for any technician specialty. Especially for home services, where your biggest challenges are the circumstances, not the repairs. And over the years, you’ll definitely pick up your own toolbox tricks.

3) Someone has repaired this appliance before you. Their work will stand for itself.

The number one rule of home appliance repair is that someone has already tried to do what you’re doing. If the appliance is more than two years old, there’s likely been another technician through. And let’s face it, most homeowners don’t call for repairs until they’ve already taken a swing at the problem. In a best-case scenario, the homeowner had no idea how to approach the problem, so they didn’t try much other than toggling the switches. But most of the time, you’re dealing with a problem someone has already monkeyed with. Someone was always there first, and you’re dealing with whatever they left behind.

So what you find says a lot about whoever was there last. See everything neatly labeled, tucked away, and unscuffed? Your predecessor was a technician who knew what they were doing. See a mess of duct-tape and wrench-scraped paint? The owner probably tied and failed at round one of repairs. See an ancient mess of corroded bolts and rotted rubber bands? An ancient DIYer was sure someone would “really” fix it a few years ago.

4) Anything can be used as a repair component.

Speaking of the crazy things you file used in and near appliances as part of a DIY repair, let’s talk materials. New repair techs don’t believe the stories of what we’ve seen done with a plastic grocery bag and roll of tape. The socks used to tie things, the silly-putty sealant attempts, and silverware propping or jamming things are only the tip of the iceberg. That barely touches on the insane things that have been done with (and to) dryer ductwork.

Granted, most of the appliances you encounter will just be a little grimy. Maybe a sock will have clogged the drain. Maybe you’ll find a little duct-tape on the plumbing. When you do come across a DIY nightmare/gem, get a picture to document 21st century human ingenuity for future generations.

5) The lengths people will go to do laundry.

While the failed repairs are sometimes unbelievably foolish, stranger are the repairs that work. It really is impressive what families will do and figure out to get their daily chores done. We have also seen some pretty genius hacks (that we had to disassemble) along the way.

We’ve seen dryer ducts repaired with plastic wrap. We’ve seen spoons used to jam dishwasher racks into place. We’ve seen all sorts of things used in the place of lost or broken appliance feet. String and hangers used to suspend dryer ducts (we mentioned the duct-art) and temporary flexible pipes have made it possible for appliances to run, even when they are very definitely broken.

Just be glad any time the innovation is external and easy to disassemble and doesn’t involve any tampered wiring.

6) Mad geniuses create fire hazards.

Speaking of those who tamper with wires, sometimes those “genius hacks” that make an appliance run also make that appliance very dangerous. There is a kind of repair you can do at home, like clearing a drain, and the kind that should only be done by trained technicians. When homeowners halfway understand how an appliance works, they can often disconnect a few wires and make an appliance run without it’s safety features, but this can and often leads to tragic at-home injuries. Disconnecting the lid switch of a top-load washer, for example.

Watch out for these fire and safety hazards when you’re repairing. Not just in the appliances, but near and behind them. Look for dangerous and non-standard wiring. And if you see something suspicious, investigate just in case there’s more irregular wiring hidden behind. The best thing you can do is not just keep yourself safe, but ensure you leave the family with a safe appliance and a safe power structure around the appliance before you sign off.

7) Appliance repair is “Big Picture” thinking.

Finally, the last thing you only realize over years of repairing home appliances is that you’re doing “Big Picture” work. Why did that mad genius disconnect the lid switch? Because he wasn’t thinking about the big picture of what might happen next. Why do people leave wires exposed once they twist a connection? They’re not thinking about the big-picture. Why do homeowners rig overly complicated dryer ducts instead of cutting the right duct-pieces to fit? Or duct-tape their vents closed? No big-picture thinking.

Just being able to see in your mind the logical conclusion of your actions is often more than your average DIY homeowner can handle. As repair technician, the things that seem most obvious to you, like a simple t-joint under the sink, might not occur to other people. And that is a pretty big “Huh” moment for most of us. Usually while looking at a Gordian Knot of duct tape.

Here at Fred’s Appliance Repair Academy, we’re constantly hosting classes for the hands-on classroom time that every technician needs. At the same time, we know exactly how valuable time on the other side can be. When you’re in the field, you’re dealing with appliances as they are really used, whether or not that’s the way they were intended to be used. In the many kitchens, utility closets, and basements you will find yourself in, there are some unforgettable lessons to be learned. Contact us for the appliance repair class schedule or for more technician insights!

How to test a gas range ignitor

Congrats to our graduating March 2024 class

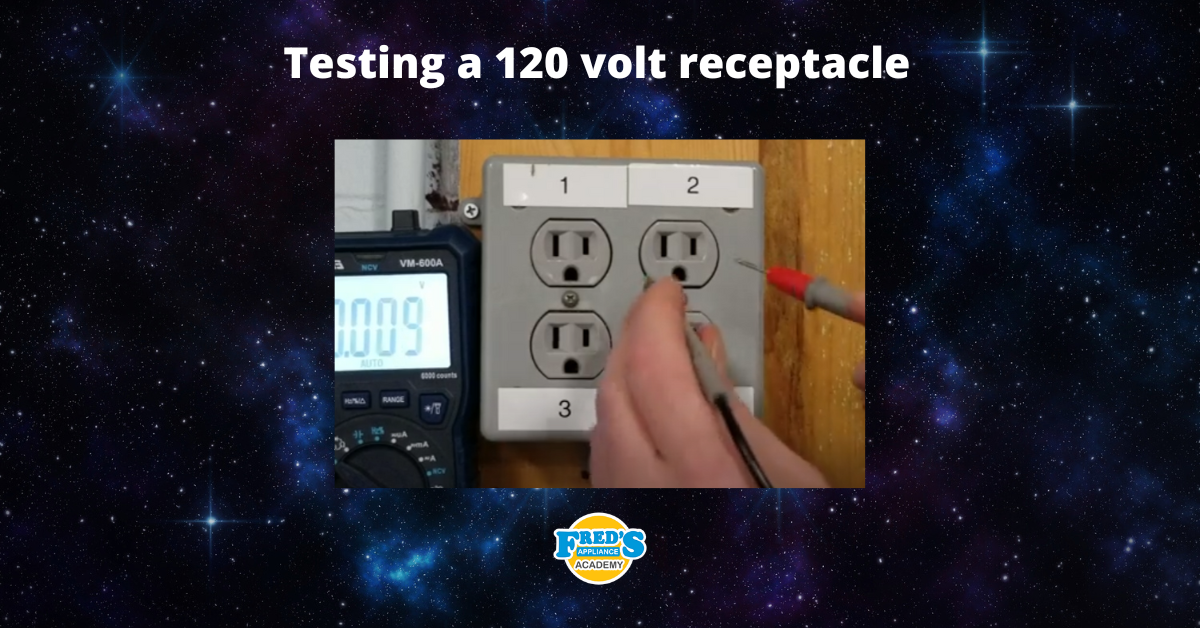

How to test a 120 volt receptacle

Congrats to our graduating February 2024 class

Why Is Your Dishwasher Soap Not Dissolving? (5 Easy Fixes)

Refrigerator Dripping Water Inside? 5 Quick Fixes

Appliance Industry 2023 Q4 Results

Congrats to our graduating January 2024 class

Clever ways to use airbags to level your appliances